Introduction

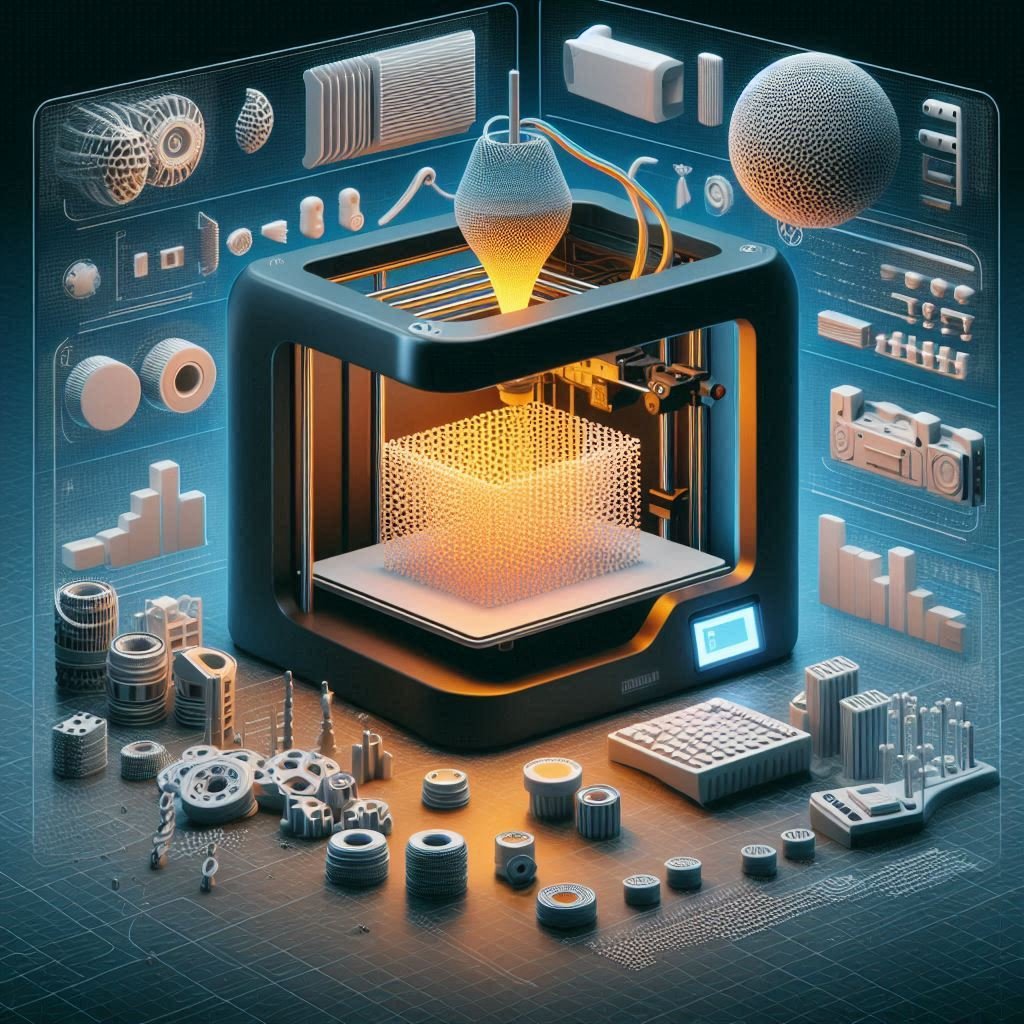

3D printing has revolutionized manufacturing, prototyping, and even art, allowing individuals and businesses to create complex three-dimensional objects from digital models. But how does a 3D printer work? Understanding the mechanics behind this incredible technology can open up new possibilities for creativity and innovation. Let’s explore the fascinating world of 3D printing and uncover the processes and components that make it all possible.

Basic Components of a 3D Printer

Frame

The frame provides the structural support for the 3D printer, ensuring stability and precision during the printing process. It can be made from various materials, including metal, plastic, or wood.

Print Bed

The print bed is the surface on which the 3D object is built. It can be heated to help with adhesion and prevent warping. Some print beds are removable or flexible to facilitate the removal of finished prints.

Extruder/Hot End

The extruder feeds the filament into the hot end, where it is melted and deposited layer by layer onto the print bed. The hot end reaches high temperatures to melt the filament, typically between 180°C and 250°C, depending on the material.

Filament

Filament is the material used for 3D printing, commonly available in spools. It comes in various types, such as PLA, ABS, and PETG, each with unique properties and applications.

Stepper Motors

Stepper motors control the movement of the print head and the print bed, ensuring precise placement of each layer. They are crucial for the accuracy and resolution of the printed object.

Control Board

The control board is the brain of the 3D printer, managing the movement of the motors, temperature of the hot end and print bed, and other critical functions. It processes the instructions from the slicing software to execute the print job.

The 3D Printing Process

Designing the 3D Model

The first step in 3D printing is designing the object using Computer-Aided Design (CAD) software. The design is saved as an STL file, which contains the geometric information of the model.

Slicing the Model

Slicing software converts the STL file into G-code, a series of instructions that the 3D printer can understand. The model is sliced into thin layers, and the G-code specifies the path and settings for each layer.

Printing the Model

The printer follows the G-code instructions to build the object layer by layer. The filament is heated and extruded through the hot end, adhering to the print bed and cooling to form a solid structure.

Types of 3D Printers

Fused Deposition Modeling (FDM)

FDM is the most common type of 3D printing technology, where thermoplastic filament is melted and extruded to build the object layer by layer. It is popular for its affordability and ease of use.

Stereolithography (SLA)

SLA uses a laser to cure liquid resin into solid layers. It is known for its high resolution and ability to create intricate details, making it ideal for jewelry, dental, and medical applications.

Selective Laser Sintering (SLS)

SLS uses a laser to sinter powdered material, such as nylon or metal, into solid layers. It is suitable for producing strong and durable parts with complex geometries.

Digital Light Processing (DLP)

DLP is similar to SLA but uses a digital light projector to cure the resin. It offers high-speed printing and fine details, often used for prototypes and small production runs.

Materials Used in 3D Printing

PLA (Polylactic Acid)

PLA is a biodegradable thermoplastic derived from renewable resources like corn starch. It is easy to print with, making it ideal for beginners and general-purpose use.

ABS (Acrylonitrile Butadiene Styrene)

ABS is a durable thermoplastic known for its strength and impact resistance. It requires a heated print bed and good ventilation due to the fumes it emits during printing.

Resin

Resin is used in SLA and DLP printers. It offers high resolution and smooth surfaces but requires post-curing with UV light to achieve full strength.

Nylon

Nylon is a strong, flexible material often used in SLS printers. It is ideal for functional parts and prototypes requiring high durability.

Metal

Metal powders, such as stainless steel, titanium, and aluminum, are used in industrial 3D printing processes like SLS and Direct Metal Laser Sintering (DMLS) to create metal parts.

Understanding the 3D Model Design

CAD Software

CAD software allows you to create detailed 3D models for printing. Popular programs include Tinkercad, Fusion 360, and Blender, each offering various features for different skill levels.

STL Files

STL (Stereolithography) files are the standard format for 3D printing, representing the surface geometry of a 3D model. They are used by slicing software to generate G-code.

Design Considerations

When designing for 3D printing, consider factors like overhangs, supports, and layer orientation to ensure successful printing and structural integrity.

Slicing the Model

Role of Slicing Software

Slicing software, such as Cura or PrusaSlicer, prepares the 3D model for printing by converting it into G-code. It allows you to adjust settings like layer height, print speed, and infill density.

G-code Generation

G-code is a language that instructs the 3D printer on how to build the model. It includes commands for movement, temperature control, and other critical functions.

Layer Height and Infill

Layer height determines the resolution and surface finish of the print, with smaller layers offering higher detail. Infill refers to the internal structure of the print, affecting its strength and weight.

Printing the Model

Initial Setup

Set up the 3D printer by loading the filament, leveling the print bed, and calibrating the extruder. Proper setup is crucial for successful printing.

Calibration and Bed Leveling

Calibrate the printer to ensure accurate movements and layer placement. Level the print bed to maintain consistent adhesion and prevent warping.

Print Monitoring and Adjustments

Monitor the print progress to catch any issues early. Make adjustments as needed, such as pausing to fix filament jams or adjusting temperature settings.

Post-Processing the Printed Object

Removing Supports

Remove any support structures used during printing. This can be done manually or with tools like pliers and cutters.

Sanding and Smoothing

Sand and smooth the print to achieve a polished finish. Start with coarse sandpaper and gradually move to finer grits.

Painting and Finishing

Apply paint or other finishes to enhance the appearance of the print. Use primers and paints compatible with the material for the best results.

Common Challenges in 3D Printing

Warping and Curling

Warping occurs when the print cools unevenly, causing corners to lift. Use a heated bed and proper adhesion techniques to minimize warping.

Layer Shifting

Layer shifting happens when the print head moves out of alignment. Ensure belts and pulleys are tight and properly calibrated to prevent this issue.

Stringing and Oozing

Stringing occurs when the filament oozes out of the nozzle during non-print moves. Adjust retraction settings to reduce stringing.

Maintenance and Care of a 3D Printer

Regular Cleaning

Keep the printer clean by removing debris and dust. Clean the nozzle and print bed regularly to ensure optimal performance.

Lubrication

Lubricate the moving parts, such as rails and bearings, to reduce friction and wear. Use appropriate lubricants recommended by the manufacturer.

Firmware Updates

Update the printer’s firmware to benefit from new features and improvements. Check the manufacturer’s website for the latest updates.

Future Trends in 3D Printing

Advancements in Materials

New materials are being developed, offering enhanced properties like increased strength, flexibility, and conductivity.

Increased Print Speeds

Technological advancements are leading to faster print speeds, reducing production times and increasing efficiency.

Larger Build Volumes

Future 3D printers are expected to offer larger build volumes, enabling the creation of bigger and more complex objects.

Conclusion

3D printing is a powerful and versatile technology that transforms digital designs into tangible objects. By understanding how 3D printers work, you can harness their potential to create everything from prototypes to final products. Whether you’re a hobbyist or a professional, 3D printing offers endless possibilities for creativity and innovation.

FAQs

How long does it take to print a 3D object?

The time it takes to print a 3D object depends on its size, complexity, and the print settings used. Small objects can take a few hours, while larger or more detailed prints can take several days.

Can 3D printers print metal objects?

Yes, some industrial 3D printers can print metal objects using processes like Selective Laser Sintering (SLS) or Direct Metal Laser Sintering (DMLS). These printers use metal powders and lasers to create solid metal parts.

What is the cost of a 3D printer?

The cost of a 3D printer varies widely based on its type, capabilities, and quality. Entry-level printers for hobbyists can start around $200, while professional and industrial models can cost several thousand dollars.

How accurate are 3D printed objects?

The accuracy of 3D printed objects depends on the printer’s resolution, the quality of the filament, and the print settings. High-resolution printers can achieve fine details and precise dimensions.

Is 3D printing safe for home use?

Yes, 3D printing is generally safe for home use. However, it’s important to use the printer in a well-ventilated area, follow safety guidelines, and handle materials and tools properly to avoid potential hazards.

Read More : How do digital cameras work?

Read More : How Far Should a Cell Phone Be from a Baby?

Read More : How to Create 3D Models for Printing